Adaptable to all actuators (hydraulic, pneumatic, electrical and climate) technologies, the basic architecture of the digital controller consists of:

- An industrial PC with peripherals

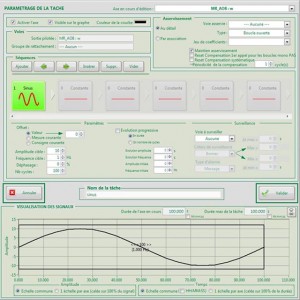

- A CAS supervisor licence

- A post-processing AfterTest licence

The set is available in two versions: Bay 19 '' or table box.

Several configurations that allow the management of 1 to 16 actuators are available.

- Multiaxial digital control platform

- Time of version 2 kHz and 5 kHz control loops

- Precision up to 24-bit analog inputs

- Deterministic real-time kernel

RACKS AND THEIR CONNECTORS

A rack of power including an emergency stop safety loop allows the power supply (s) steering rack (s).

A steering rack includes standard connectivity that allows you to connect all your actuators and sensors.

These will be scalable using the range of the following modules: CANopen, DeviceNet, Ethernet, PROFINET, SERCOS, PROFIBUS, Fieldbus, Interbus

Analog inputs and outputs: 0 – 10V, ±10V, 0-20mA, 4-20mA, thermocouple (J, K, L, U,…), RTD probes (PT100, PT1000,…), bridge of gauges, Ethercat, SSI, SinCos, incremental sensors, RS232, RS422/485, IEEE,…